Regenerative Incineration Technology

Home / Products / EXHAUST GAS TREATMENT / Regenerative Incineration Technology

Regenerative Incineration Technology

Heat recovery as high as 95%-97% can be achieved

VOC destruction rates of ≥98%

Low NOx Burners

Reliable valve design enables VOC removal rates of up to 99%

Multiple-chamber RTO systems can be designed and manufactured

User friendly design for rapid installation & ease of maintenance

PLC automatic control

Variable frequency drive(VFD) for reduced power consumption

Integrated VPN for remote troubleshooting & view of real time operations

Very low NOx generation

- Product Description

- Specification

- Product Feature

- More Details

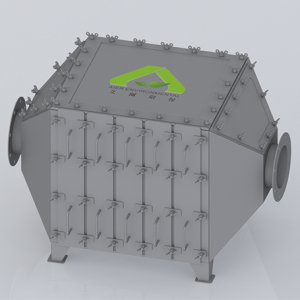

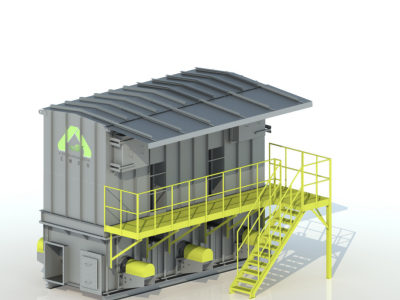

Product Description

Regenerative Thermal Oxidizer equipment is abbreviated as RTO, and its full name is (Regenerative Thermal Oxidizer). The basic principle is to oxidize organic waste gases (VOCs) under high temperature conditions (≥760°C) to generate CO2+H2O, with a purification efficiency of up to 99%. The high-temperature gas generated by the oxidation flows through the special ceramic regenerator, causing the ceramic body to heat up and “storage heat”. The next process is that the waste gas passes through the “heat-storage” ceramics, transferring the heat of the ceramic to the waste gas, and the organic waste gas passes through Ceramics serve as a heat exchanger carrier and repeatedly perform heat exchange, thereby saving fuel consumption for exhaust gas heating, reducing operating costs, and the heat recovery efficiency is as high as 95%. Under medium and high concentration conditions, RTO can output waste heat to the outside and utilize it through steam, hot air, hot water, etc., to achieve economic benefits while meeting environmental protection goals.

Specification

| Model | Temperature | Treated air volume | Specification |

|---|---|---|---|

| AR-RTO3Q-10K | 760~950 | 10000 | 6200*2500*5100 |

| AR-RTO3Q-15K | 760~950 | 15000 | 7100*2500*5300 |

| AR-RTO3Q-20K | 760~950 | 20000 | 9000*2500*5500 |

| AR-RTO3Q-25K | 760~950 | 25000 | 9800*2500*5500 |

| AR-RTO3Q-30K | 760~950 | 30000 | 9400*3000*6000 |

| AR-RTO3Q-35K | 760~950 | 35000 | 10500*3000*6000 |

| AR-RTO3Q-40K | 760~950 | 40000 | 9400*4000*6200 |

| AR-RTO3Q-50K | 760~950 | 50000 | 11200*4000*46400 |

Product Feature

-

1

Heat recovery as high as 95%-97% can be achieved

-

2

VOC destruction rates of ≥98%

-

3

Low NOx Burners

-

4

Reliable valve design enables VOC removal rates of up to 99%

-

5

Multiple-chamber RTO systems can be designed and manufactured

-

6

User friendly design for rapid installation & ease of maintenance

-

7

PLC automatic control

-

8

Variable frequency drive(VFD) for reduced power consumption

-

9

Integrated VPN for remote troubleshooting & view of real time operations

-

10

Very low NOx generation